Imikhiqizo

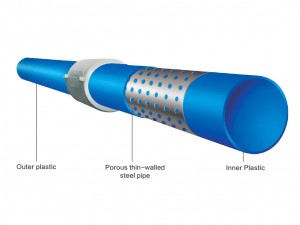

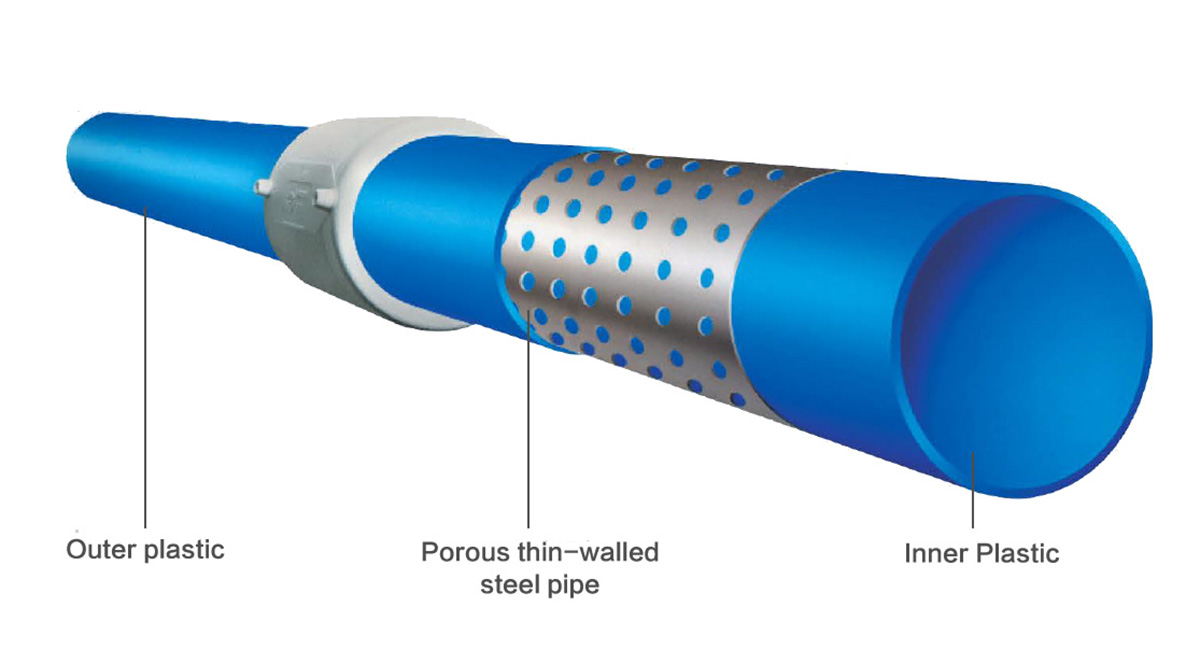

Ipayipi lensimbi elinezimbobo Ipayipi le-PE Ukuze uthole amanzi

Isicelo

Ipayipi elihlanganisiwe lensimbi elinezimbobo le-polyethylene lenziwe ngensimbi egoqelwe ebandayo kanye ne-thermoplastics njengezinto zokusetshenziswa, futhi amapayipi ensimbi anezindonga ezincane anezimbobo akhiwa i-argon arc butt welding noma i-plasma spiral welding asetshenziswa njengeziqinisi. Izendlalelo zangaphandle nezingaphakathi ziyi-thermoplastic ehlanganisiwe enezinhlangothi ezimbili. Uhlobo olusha lwepayipi lokucindezela eliyinhlanganisela, Ngenxa yokuthi ipayipi lensimbi elinezimbobo ezincane elinezindonga eziqinile ligoqwe nge-thermoplastic eqhubekayo, leli payipi eliyinhlanganisela aligcini nje ngokunqoba ukushiyeka okukhona kwamapayipi ensimbi namapayipi epulasitiki, kodwa futhi linokuqina kwamapayipi ensimbi nokugqwala. ukumelana namapayipi epulasitiki. Kuyisixazululo sezimboni ze-petroleum kanye namakhemikhali. Kuyipayipi elidingeka ngokuphuthumayo lamapayipi amakhulu naphakathi nendawo aqinile emkhakheni wemithi, ukudla, izimayini, igesi kanye neminye imikhakha. Kuphinde kube yimpumelelo yezinguquko kwezobuchwepheshe ukuxazulula ipayipi elikhulu lokwakha kanye nokuhlinzekwa kwamanzi kamasipala. Iwuhlobo olusha lwepayipi eliyinhlanganisela ku-21stikhulu leminyaka.

Izici

Amandla aphezulu kanye nokunwetshwa komugqa okuphansi.

Ngenxa yokuqiniswa kohlaka lwensimbi, ipayipi eliyinhlanganisela yensimbi enezimbobo linamandla aphakeme, ukuqina okuphezulu kanye nokumelana nomthelela kunepayipi lepulasitiki. Ngesikhathi esifanayo, umphumela wokuvimbela wefreyimu yensimbi uphinde wenze ipayipi ye-perforated steel strip plastic composite ibe а umugqa ophansi ofana nowombhobho wensimbi. Ukunwetshwa kwe-coefficient kanye nokumelana ne-сгеер.

Ukugqwala nokumelana nokugqoka.

Izinto ze-polyethylene ezinobukhulu obuphezulu ezikhethelwe umugqa wensimbi onezimbobo ipayipi eliyinhlanganisela yepulasitiki iyi-crystalline non-polar polymer material enezakhiwo zamakhemikhali ezizinzile, ukumelana ne-asidi eminingi, usawoti we-alkali kanye nemidiya ye-organic, kanye nokugqwala kwe-electrochemical. Ukusebenza kokugaya kuphakeme izikhathi ezi-5 kunamapayipi ensimbi.

Imingcele Yezobuchwepheshe

Lo mkhiqizo usebenzisa i-polyethylene resin ekhethekile, futhi izakhiwo zayo zomzimba nezemishini zihlangabezana nezinga le-Ministry of Construction CJ/T181-2003 kanye nezinga lemboni yamakhemikhali HG/T3706-2014.

| Usayizi wokucaciswa, ukuchezuka kanye nengcindezi encane: ukuhlangabezana nezidingo ze-Ministry of Construction standard CJ/T181-2003 | |||||

| I-diameter yangaphandle encane kanye nokuchezuka | Ukujiya kodonga lokuzisholo nokuchezuka | Ngaphandle kokuyindilinga | Ingcindezi yamagama | Inani elincane lika-S | Ubude nokuchezuka |

| I-Dn(mm) | I-En(mm) | Mm | Mpa | Mm | mm |

| 50+0.5 0 | 4.0+0.5 9 | 1.0 | 2.0 | 1.5 | 6000+20 0 9000+20 0 12000+20 0 |

| 60+0.6 0 | 4.5+0.6 0 | 1.26 | 2.0 | 1.5 | |

| 75+0.7 0 | 5.0+0.7 0 | 1.5 | 2.0 | 1.5 | |

| 90+0.9 0 | 5.5+0.8 0 | 1.8 | 2.0 | 1.5 | |

| 110+1.0 0 | 6.0+0.9 0 | 2.2 | 2.0 | 1.5 | |

| 140+1.1 0 | 8.0+1.0 0 | 2.8 | 1.6 | 2.5 | |

| 160+1.2 0 | 10.0+1.1 0 | 3.2 | 1.6 | 2.5 | |

| 200+1.3 0 | 11.0+1.2 0 | 4.0 | 1.6 | 2.5 | |

| 225+1.4 0 | 11.5+2.4 0 | 4.5 | 1.6 | 2.5 | |

| 250+1.4 0 | 12.0+1.3 0 | 5.0 | 1.6 | 3.5 | |

| 280+1.5 0 | 12.5+2.6 0 | 5.6 | 1.6 | 3.5 | |

| 315+1.6 0 | 13.0+1.4 0 | 6.3 | 1.25 | 3.5 | |

| 355+1.6 0 | 14.0+2.8 0 | 7.1 | 1.25 | 3.5 | |

| 400+1.6 0 | 15.0+1.5 0 | 8.0 | 1.25 | 3.5 | |

| 500+1.7 0 | 16.0+1.6 0 | 10.0 | 1.0 | 4.0 | |

| 630+1.8 0 | 17.0+1.7 0 | 12.3 | 1.0 | 4.0 | |

| Qaphela: Ukucindezela okulinganiselwe kwepayipi elihlanganisiwe kuwukucindezela okukhulu okuvunyelwe ukuba ipayipi lihambise amanzi ku-20 ° С. Uma izinga lokushisa lishintsha, ingcindezi yokusebenza kufanele ilungiswe ngokuvumelana ne-coefficient yokucindezela kwezinga lokushisa kwezinto ezihlukahlukene. Inani lika-S: ibanga ukusuka kububanzi obungaphandle bokuqiniswa ukuya endaweni yangaphandle yepayipi. | |||||

| Izidingo zokusebenza ngokomzimba nangokomshini | ||

| Iphrojekthi | Ukusebenza | |

| Ukuqina kwendandatho, KN/m2 | >8 | |

| Ukuhlola okuyisicaba | Ayiphukile | |

| Ukuncipha kwe-longitudinal (100°С, gcina ihora elingu-1) | <0.3% | |

| Ukuhlolwa kwe-hydraulic | Izinga lokushisa: 20 ° С; Isikhathi: 1h; Ingcindezi encane x2 | Ayiphukile |

| Izinga lokushisa: 80 ° С; Isikhathi: 165h; Ingcindezi: Ingcindezi encane x2x0.71 (isici sokunciphisa) | ||

| Ukuhlolwa kwengcindezi yokuqhuma | Izinga lokushisa: 20°С, ingcindezi yokuqhuma ≥ ingcindezi encane x3.0 | Ukuqhuma |

| Isikhathi sokungeniswa kwe-oxidation (200°С), imiz | ≥20 | |

| *Ukumelana nesimo sezulu* Ukwamukelwa okunqwabelanayo kwamapayipi≥3.5J/m2 Ngemva kokuguga amandla | Ukuhlolwa kwe-hydraulic, izimo zokuhlola ziyefana nento 3 kuleli thebula | Ayiphukile |

| Ukuhlolwa kwengcindezi yokuqhuma, izimo zokuhlola ziyefana nento engu-4 kuleli thebula | Hhayi ukuqhuma | |

| Isikhathi sokungeniswa kwe-oxidation (200°С), imiz | ≥10 | |

*Ngepayipi lenhlanganisela eluhlaza okwesibhakabhaka kuphela*