Imikhiqizo

Ipayipi lensimbi enezimbobo Ipayipi le-PE Lokumelana nokushisa

Isicelo

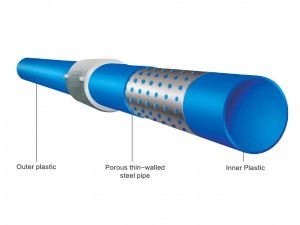

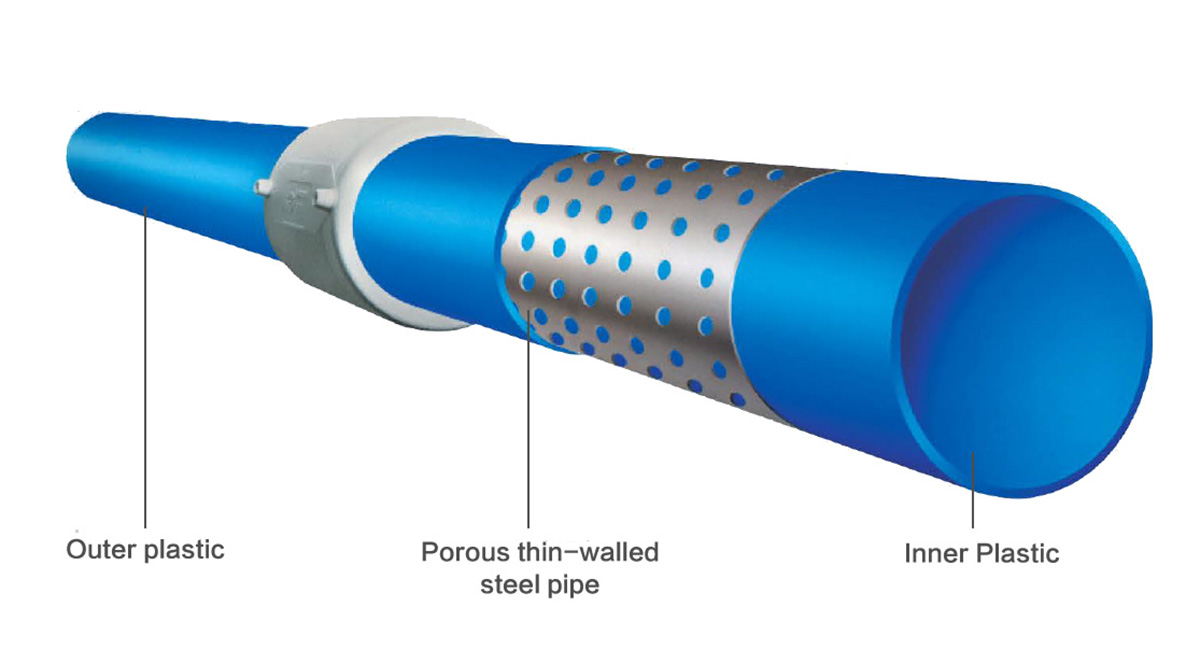

Ipayipi elihlanganisiwe lensimbi elinezimbobo le-polyethylene lenziwe ngensimbi egoqelwe ebandayo kanye ne-thermoplastics njengezinto zokusetshenziswa, futhi amapayipi ensimbi anezindonga ezincane anezimbobo akhiwa i-argon arc butt welding noma i-plasma spiral welding asetshenziswa njengeziqinisi. Izendlalelo zangaphandle nezingaphakathi ziyi-thermoplastic ehlanganisiwe enezinhlangothi ezimbili. Uhlobo olusha lwepayipi lokucindezela eliyinhlanganisela, Ngenxa yokuthi ipayipi lensimbi elinezimbobo ezincane elinezindonga eziqinile ligoqwe nge-thermoplastic eqhubekayo, leli payipi eliyinhlanganisela aligcini nje ngokunqoba ukushiyeka okukhona kwamapayipi ensimbi namapayipi epulasitiki, kodwa futhi linokuqina kwamapayipi ensimbi nokugqwala. ukumelana namapayipi epulasitiki. Kuyisixazululo sezimboni ze-petroleum kanye namakhemikhali. Kuyipayipi elidingeka ngokuphuthumayo lamapayipi amakhulu naphakathi nendawo aqinile emkhakheni wemithi, ukudla, izimayini, igesi kanye neminye imikhakha. Kuphinde kube yimpumelelo yezinguquko kwezobuchwepheshe ukuxazulula ipayipi elikhulu lokwakha kanye nokuhlinzekwa kwamanzi kamasipala. Iwuhlobo olusha lwepayipi eliyinhlanganisela ku-21stikhulu leminyaka.

Izici

Ukuqina kwendandatho ephezulu kanye nokuqina okuphezulu

Ipayipi eliyinhlanganisela yensimbi enezimbobo inokuqina okuphezulu kwendandatho kanye nokuqina okuphezulu eduze kwamapayipi ensimbi, futhi ifaneleka ngokukhethekile ukubekwa phezulu kwamaphaseji amapayipi.

Ukusebenza kokuphepha

Uhlaka oluqinisiwe lwepayipi eliyinhlanganisela yebhande lensimbi elinembobo kanye nezinto zokusetshenziswa zepulasitiki eziqukethwe ngokuphelele ngenetha enezimbobo, futhi kukhona ukukhathazeka ngokuxebuka kwepulasitiki yodonga lwangaphakathi nangaphandle kanye nohlaka lwensimbi. Ukuxhumeka kwe-fusion kagesi kunokumelana okuqinile nomdwebo we-axial, futhi isistimu yepayipi inokwethenjelwa okuphezulu. Ngaphansi kwezimo ezijwayelekile, impilo yesevisi ingafinyelela eminyakeni engama-50.

Imingcele Yezobuchwepheshe

| I-diameter yangaphandle encane kanye nokuchezuka | Ukujiya kodonga lokuzisholo nokuchezuka | Ingcindezi yamagama | Inani elincane lika-S |

| I-Dn(mm) | I-En(mm) | Mpa | Mm |

| 50+0.5 0 | 6.0+1.5 9 | 2.0 | 1.5 |

| 63+0.6 0 | 6.5+1.5 0 | 2.0 | 1.5 |

| 75+0.7 0 | 7.0+1.5 0 | 2.0 | 1.5 |

| 90+0.9 0 | 8.0+1.5 0 | 2.0 | 1.5 |

| 110+1.0 0 | 9.0+1.5 0 | 2.0 | 1.5 |

| 140+1.1 0 | 9.0+1.5 0 | 1.6 | 2.0 |

| 160+1.2 0 | 10.0+1.8 0 | 1.6 | 2.0 |

| 200+1.3 0 | 11.0+2.0 0 | 1.6 | 2.0 |

| 225+1.4 0 | 11.5+2.2 0 | 1.6 | 2.0 |

| 250+1.4 0 | 12.0+2.2 0 | 1.6 | 2.0 |

| 280+1.5 0 | 12.5+2.3 0 | 1.6 | 2.5 |

| 315+1.5 0 | 13.0+2.5 0 | 1.25 | 2.5 |

| 355+1.6 0 | 14.0+2.5 0 | 1.25 | 2.5 |

| 400+1.6 0 | 15.0+2.8 0 | 1.25 | 2.5 |

| 450+1.8 0 | 15.0+2.8 0 | 1.25 | 2.5 |

| 500+2.0 0 | 16.0+3.0 0 | 1.25 | 2.5 |

| Izici ezingokomzimba zepayipi elihlanganisiwe | ||

| Iphrojekthi | Imfuneko yokusebenza | |

| Ukuqina kokuqhekeka ngaphansi kwengcindezi | Ayikho imifantu | |

| Izinga lokuncipha longitudinal (110°С, gcina ihora elingu-1) | <0.3% | |

| Ukuhlolwa kwe-hydraulic | Izinga lokushisa: 20 ° С; Isikhathi: 1h; Ingcindezi: umfutho wegama x1.5 | Ayiphukile Akukho ukuvuza |

| Izinga lokushisa: 70 ° С; Isikhathi: 165h; Ingcindezi: Ingcindezi encane x1.5x0.76 | ||

| Izinga lokushisa: 85 ° С; Isikhathi: 165h; Ingcindezi yokuqhuma ≥ ingcindezi encane x1.5x0.66 | ||